[Cable & Harness Defects] Testing for Terminal half-insertion at connector

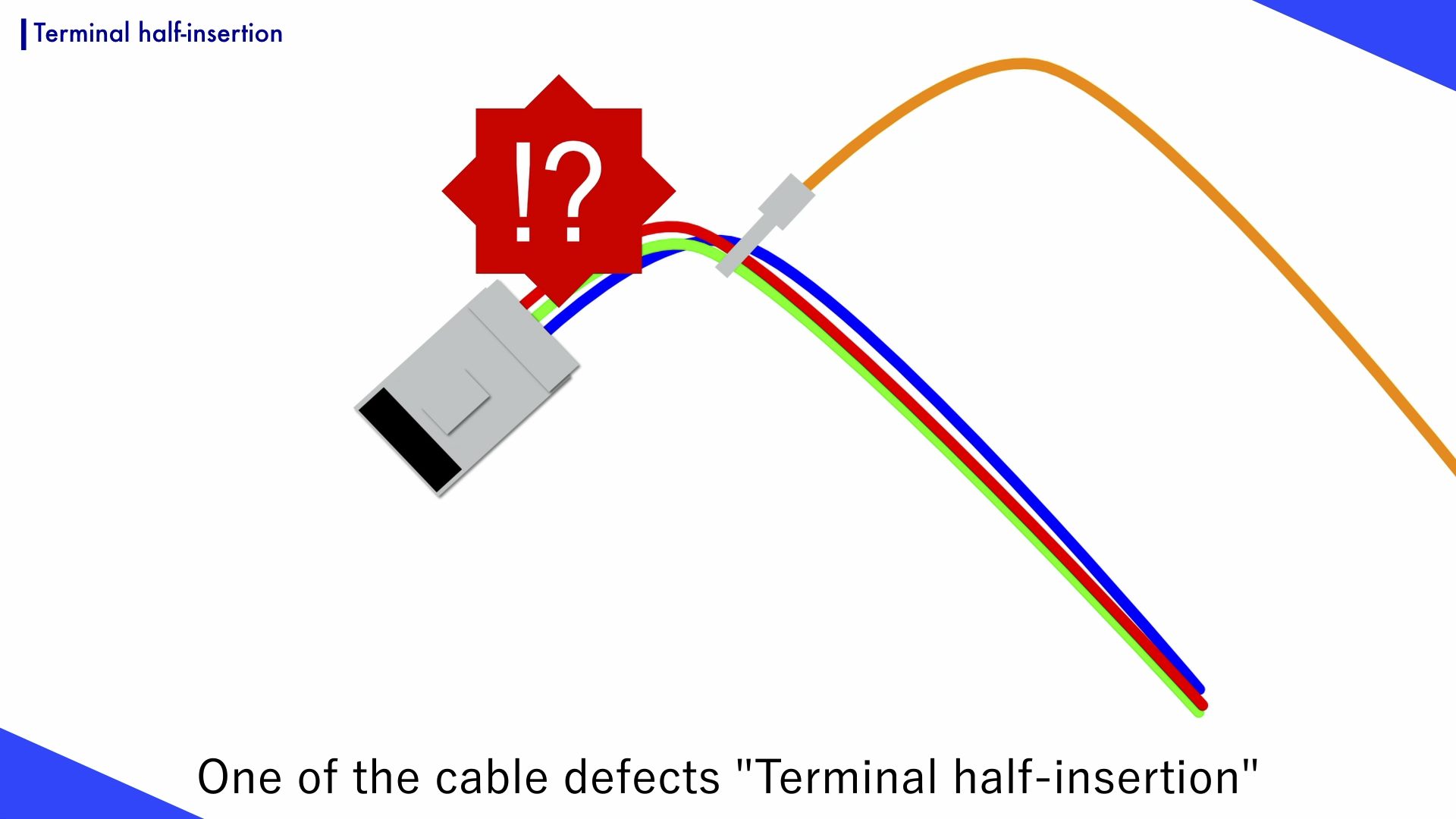

Terminal half-insertion is a manufacturing error commonly found in cables and harnesses. In this video, we will introduce how this error occurs and a test to prevent outflow.

Why does "Half-insertion of terminal" occur?

In many cases, the cause of terminal disconnection is half-insertion of terminals. What is terminal half-insertion? This is a condition in which the terminal is not fully inserted into the connector and the locking is not functioning. Since housing is done by hand, errors can inevitably occur. Therefore, it is necessary to perform a test to detect errors. There are five types of electrical tests for harnesses. What is an effective test for detecting terminal half-insertion?? It is difficult to detect by wiring testing and resistance testing since the resistance value is not expected to fluctuate even in the condition. Also, applying a high voltage does not cause an error.

Detection of terminal half-insertion at connector by momentary disconnection testing

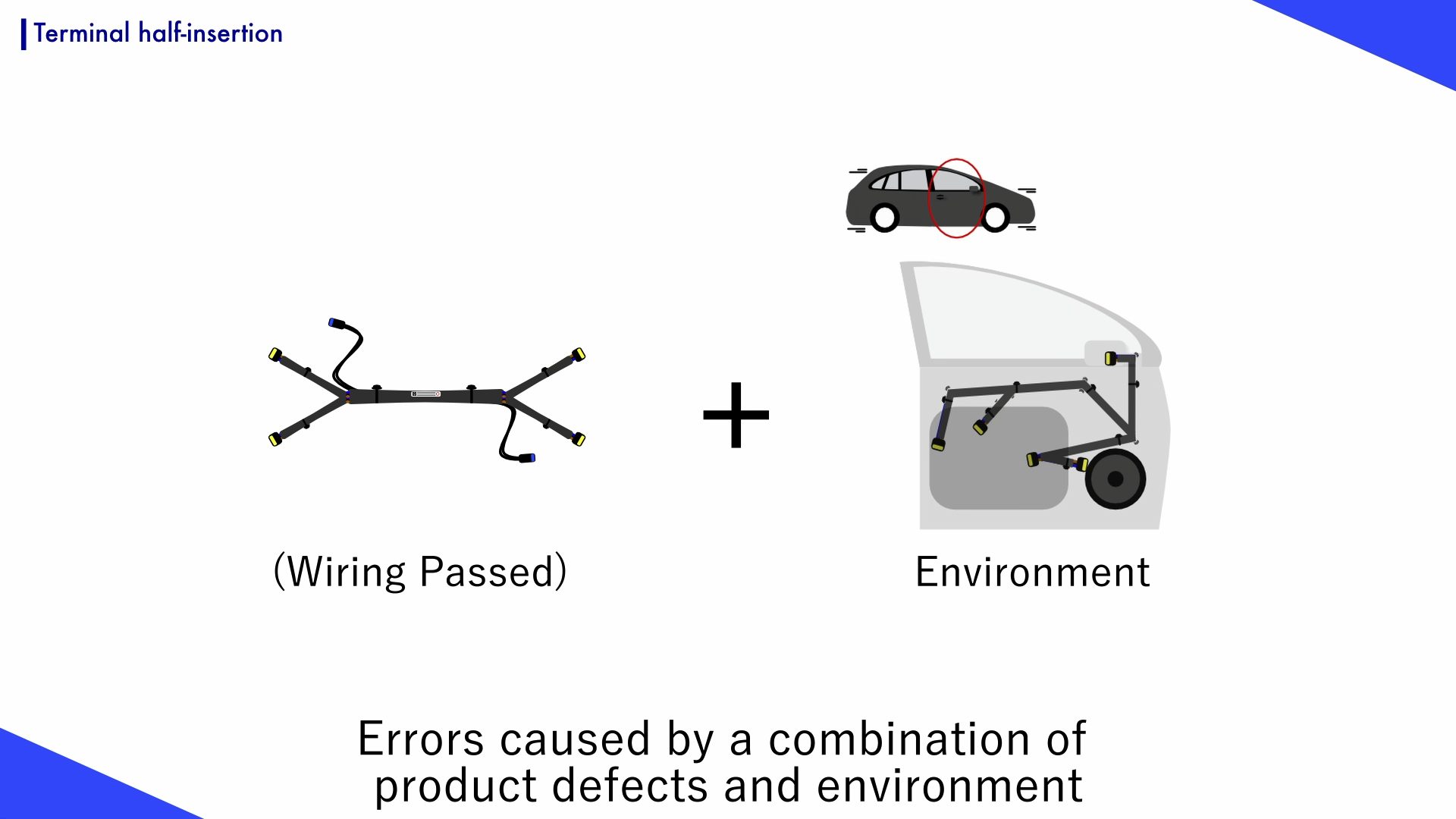

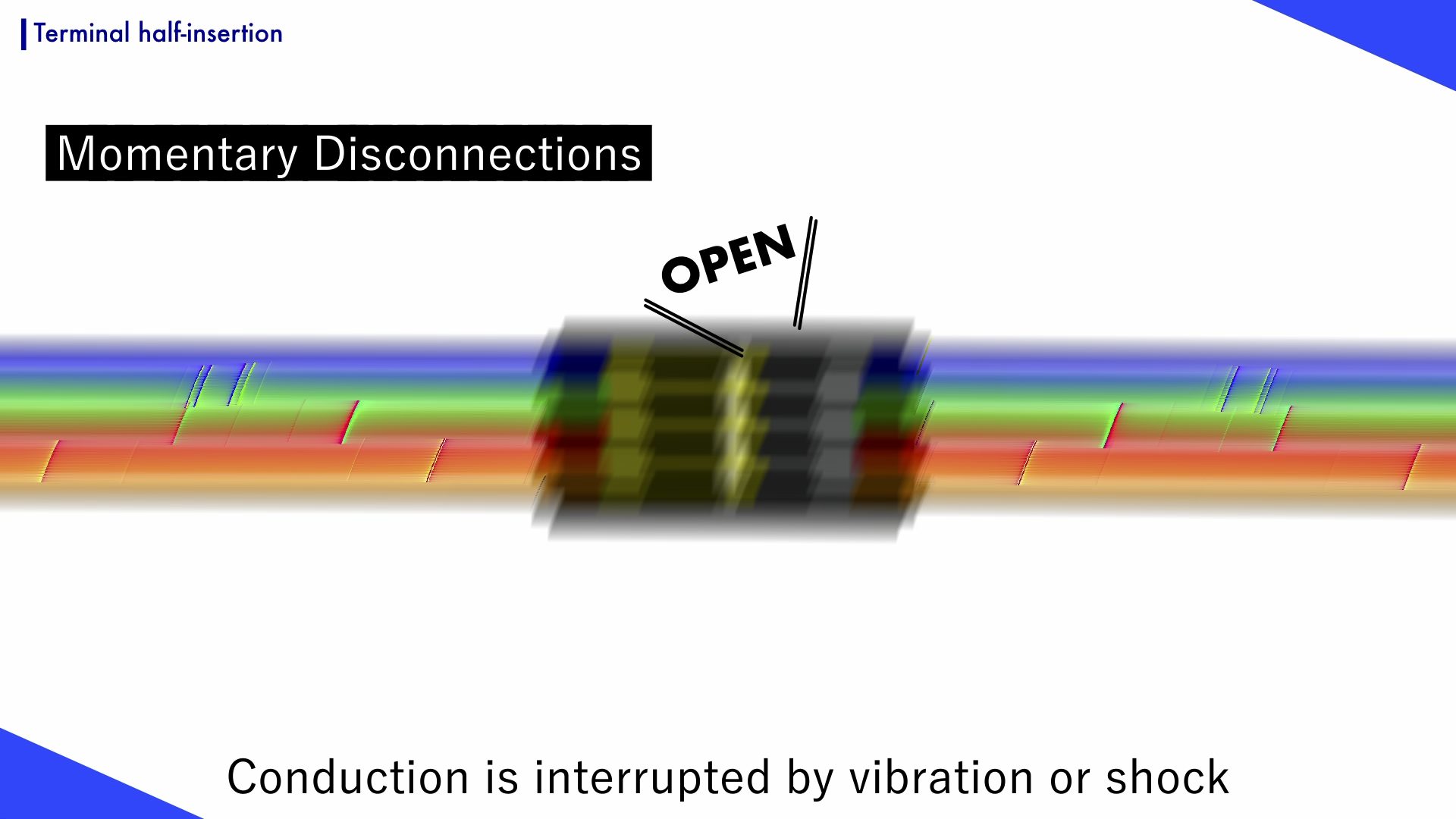

Momentary disconnection testing is effective in detecting terminal half-insertion. Momentary disconnection is caused by a combination of product defects and the environment. If the terminals are in contact, even slightly, conduction is possible. However, if the cable is defective, vibration or shock will cause momentary disconnection. In the case of half-insertion, pulling the terminal loosens it, resulting in a momentary disconnection. Momentary disconnection testing is very effective as a countermeasure against the outflow of the terminal half-insertion products. Demand for this testing is increasing as devices become more functional and complicated. There are some old cable harness testers that are not available for momentary disconnection testing. In many cases, our customers replace their old tester with our products in order to implement the momentary disconnection testing. We would like to introduce methods to prevent terminal half-insertion in the automotive industry. First of all, a retainer is attached as a part to prevent half-insertion. In addition, fixtures are used for test adapters. The fixture is a pseudo-connector using a spring probe, and a lever is used to apply a certain amount of pressure to the terminal to make it conduct. If the terminal is not inserted correctly, it is pushed out. In addition, a momentary disconnection testing can be performed to further improve the quality of the fixture. The fixtures are also being introduced outside of the automotive industry. Please contact us about cable harness testers and fixtures to prevent terminal disconnection.

Click here for NMG+ Hi-Pot Cable Harness Tester- Product Search

- Inspection Spec

- Category

- Options

- Discontinued Product

- All Products