[Cable & Harness Defects] Testing for Improper Pressure Welding in IDC Cables

Improper pressure welding is a manufacturing error commonly found in IDC cables. In this video, we will demonstrate how this error occurs and the importance of harness testing in preventing issues.

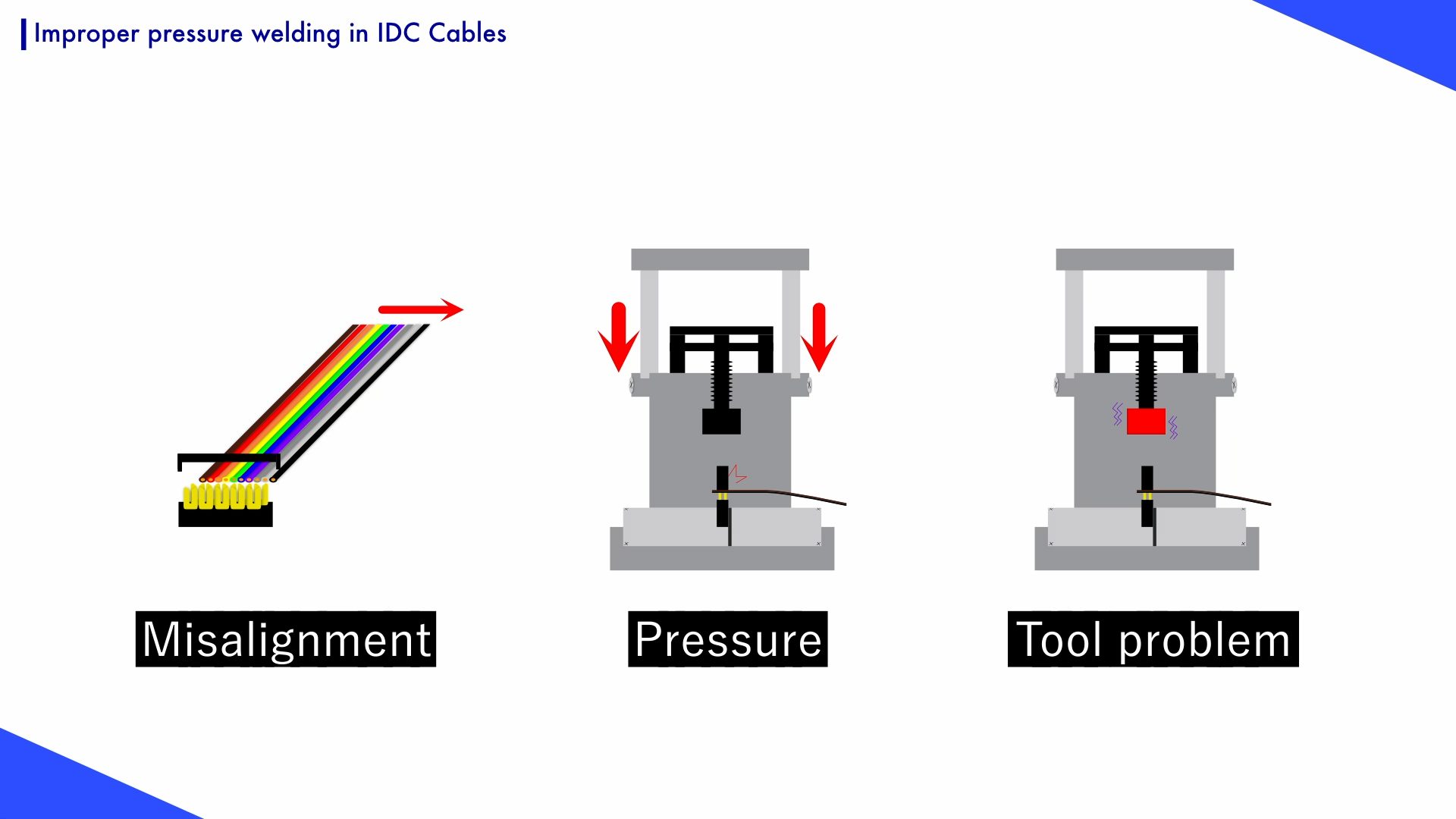

Why do IDC cable defects occur?

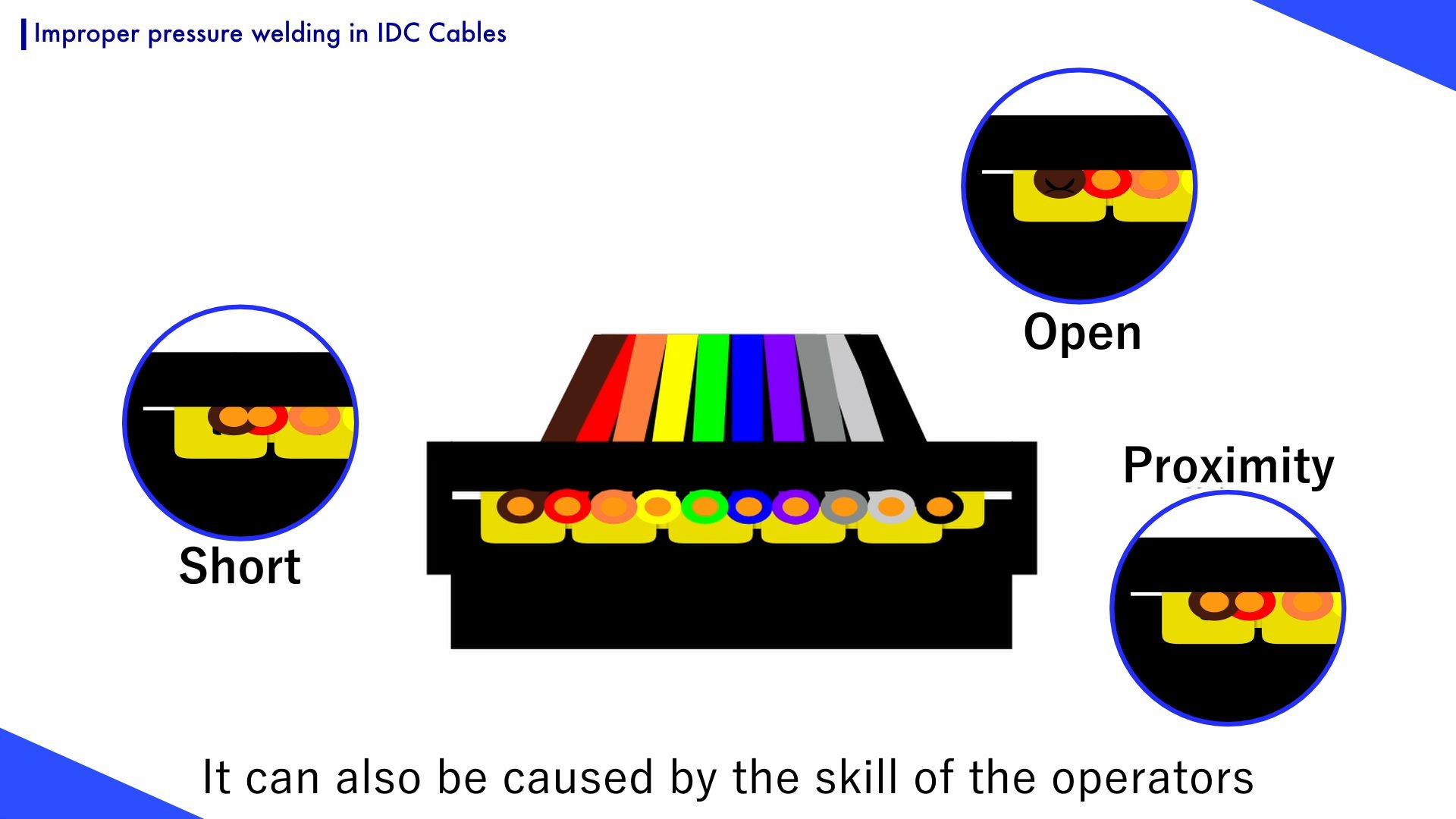

IDC cable defects can arise from cable misalignment during the pressure welding process, excessive or insufficient pressure, and inadequate tool maintenance. Such improper pressure welding can lead to unintended shorts, disconnections, or contact proximity.

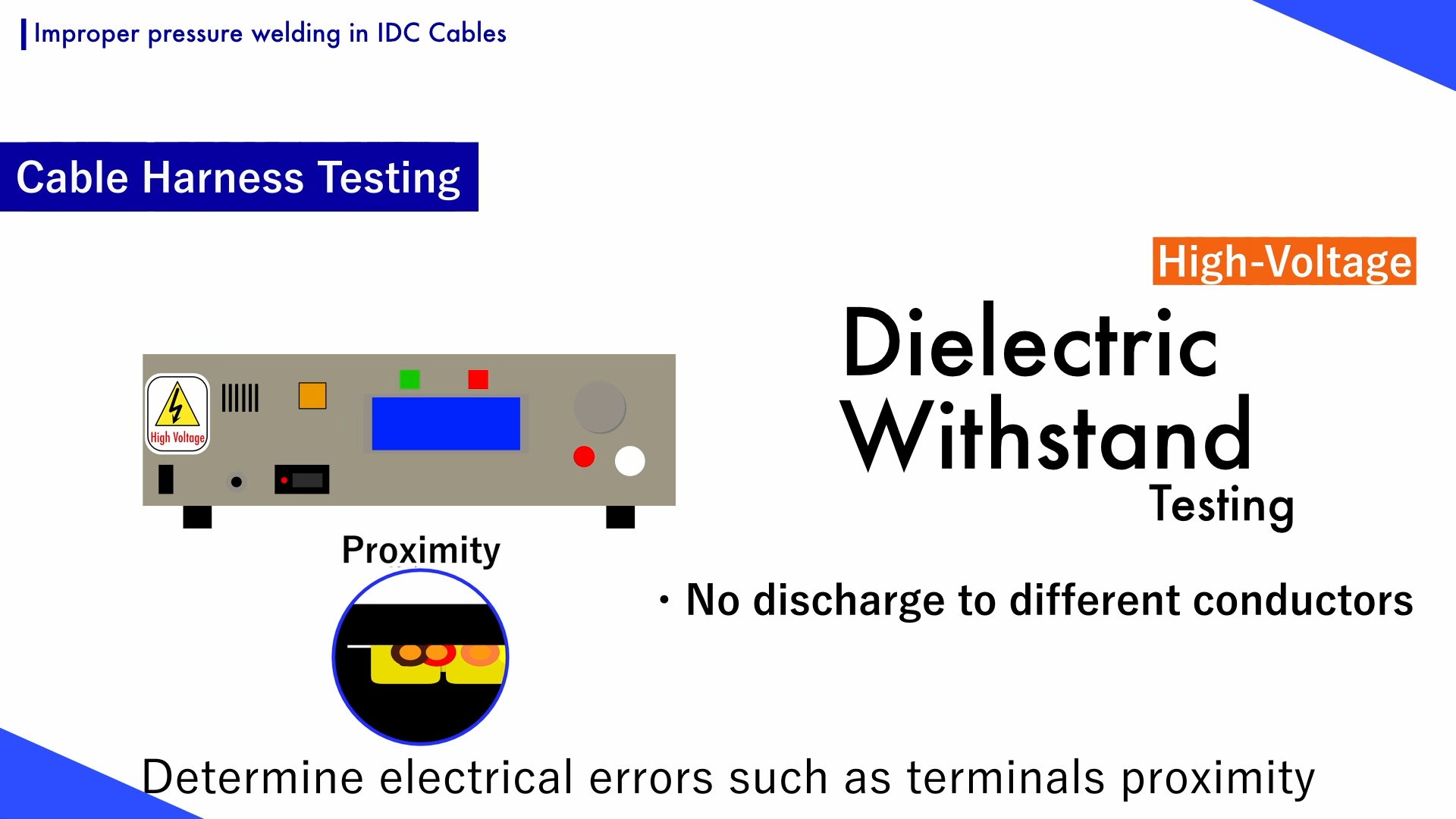

Testing of IDC cables to prevent defect outflow

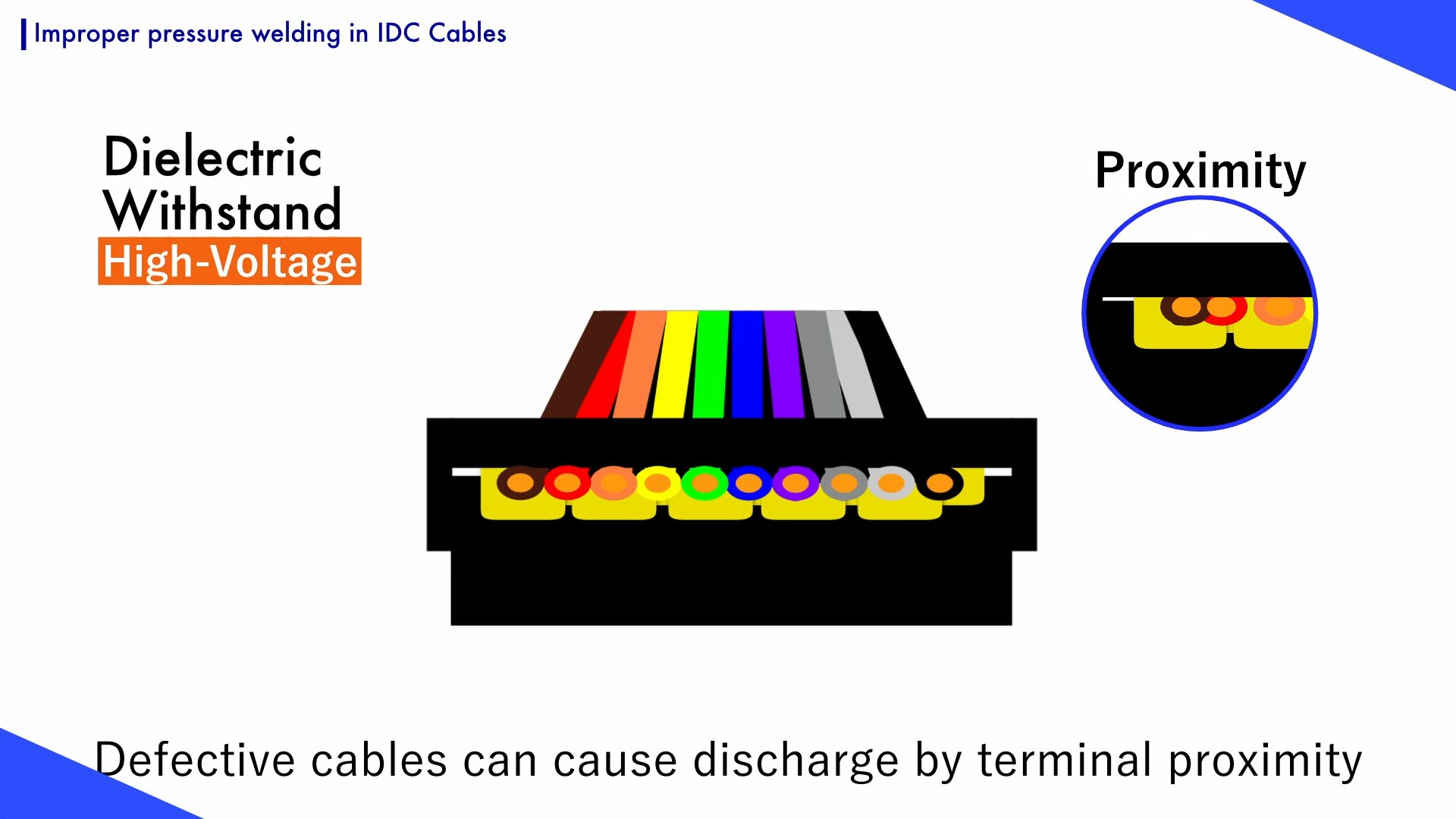

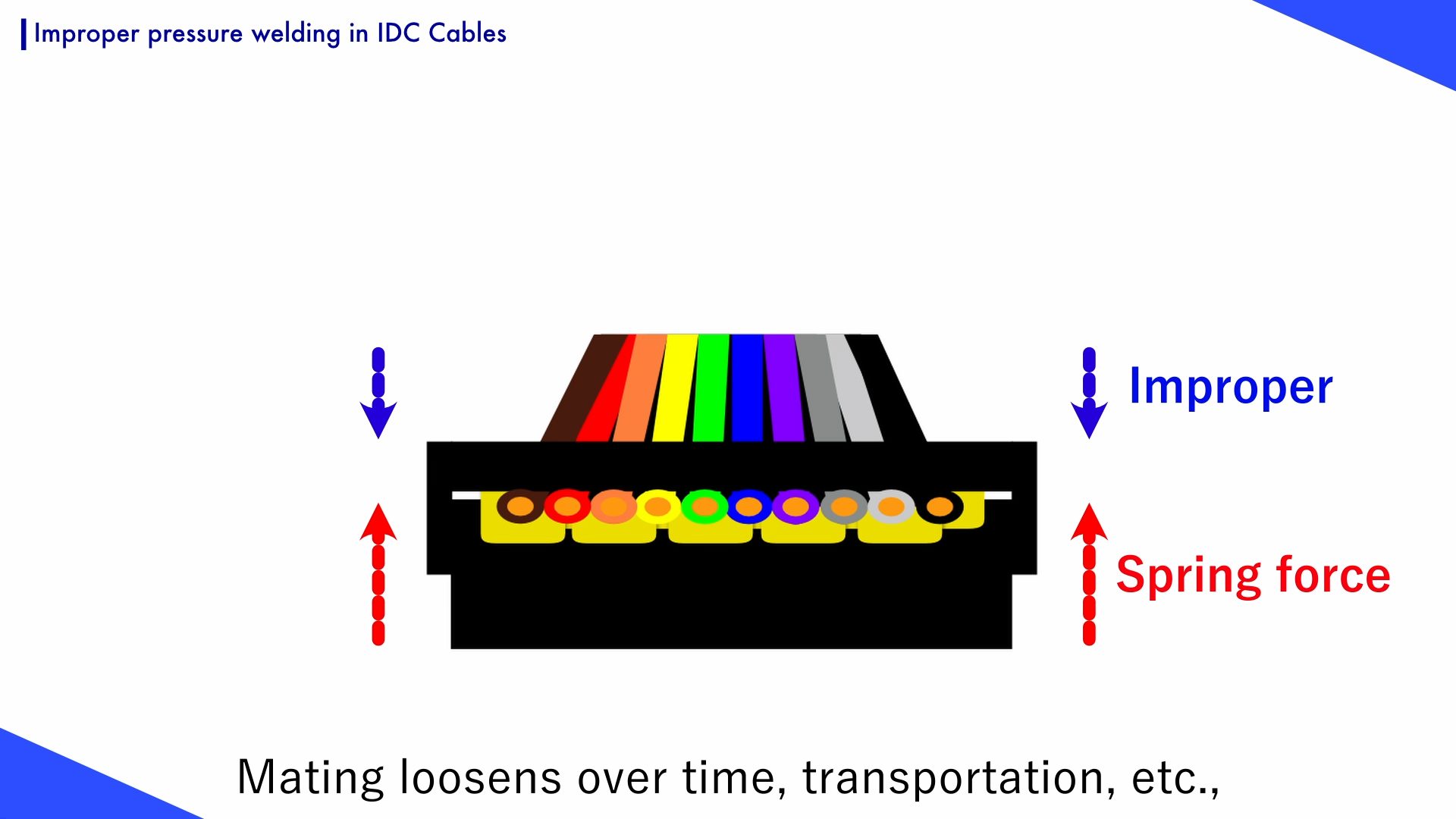

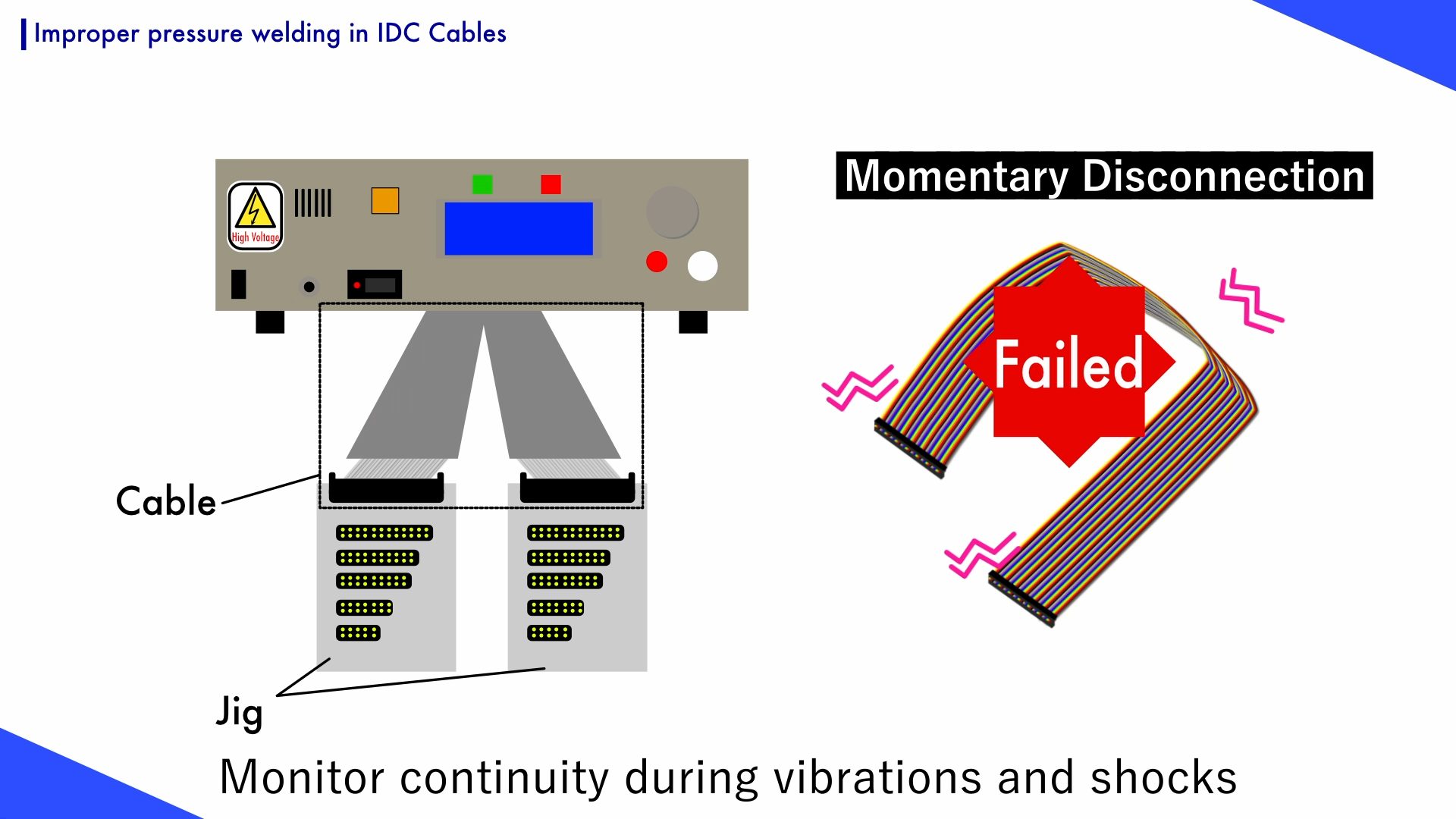

For IDC cables, both wiring testing and withstand voltage testing are essential. Additionally, the implementation of momentary disconnection testing has proven effective in enhancing product quality. Wiring testing checks the wiring and ensures there are no unintended shorts or disconnections. With withstand voltage testing, high voltage is applied to detect any discharge phenomenon. Defective IDC cables can cause issues during withstand voltage testing due to terminal proximity or misalignment. IDC cables typically have a rated voltage of around 300 volts. It is crucial to avoid using IDC cables on the test adapter side during high-voltage testing. Also, the adjacent pins are self-explanatory. Employing the flat application method allows for withstand voltage testing with just two applications. The adoption of momentary disconnection testing is on the rise due to increasing demand. Normally, connectors and cables maintain continuity through the metal's springiness. Improper pressure welding can lead to loose contacts over time, resulting in failures. Many cases of defective products have been reported due to vibration or shock during transportation or field use, even when they initially passed the wiring test. Momentary disconnection testing is becoming increasingly important for devices with advanced functionality to prevent momentary disconnection defects caused by vibration or shock.

Cable Harness Testers "nacman series" for testing IDC cables

We recommend using "NMG+ Hi-Pot Cable Harness Tester" to identify pressure welding defects in IDC cables. We suggest utilizing our well-proven nacman series testers to enhance product quality.- Product Search

- Inspection Spec

- Category

- Options

- Discontinued Product

- All Products