[Cable & Harness Defect] Cable Harness Testing for A Loose Female Terminal

Why does female terminal loosening occur?

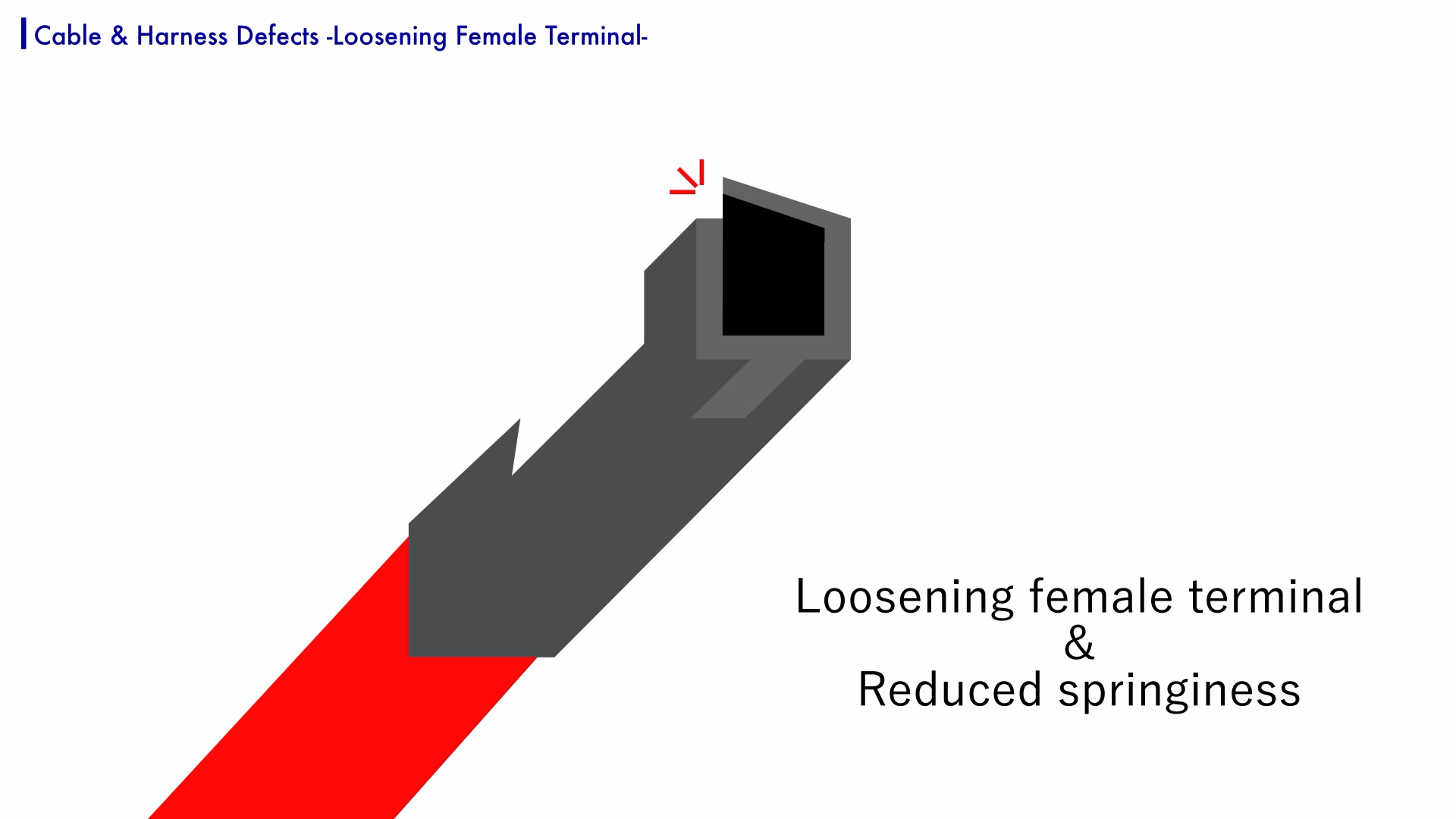

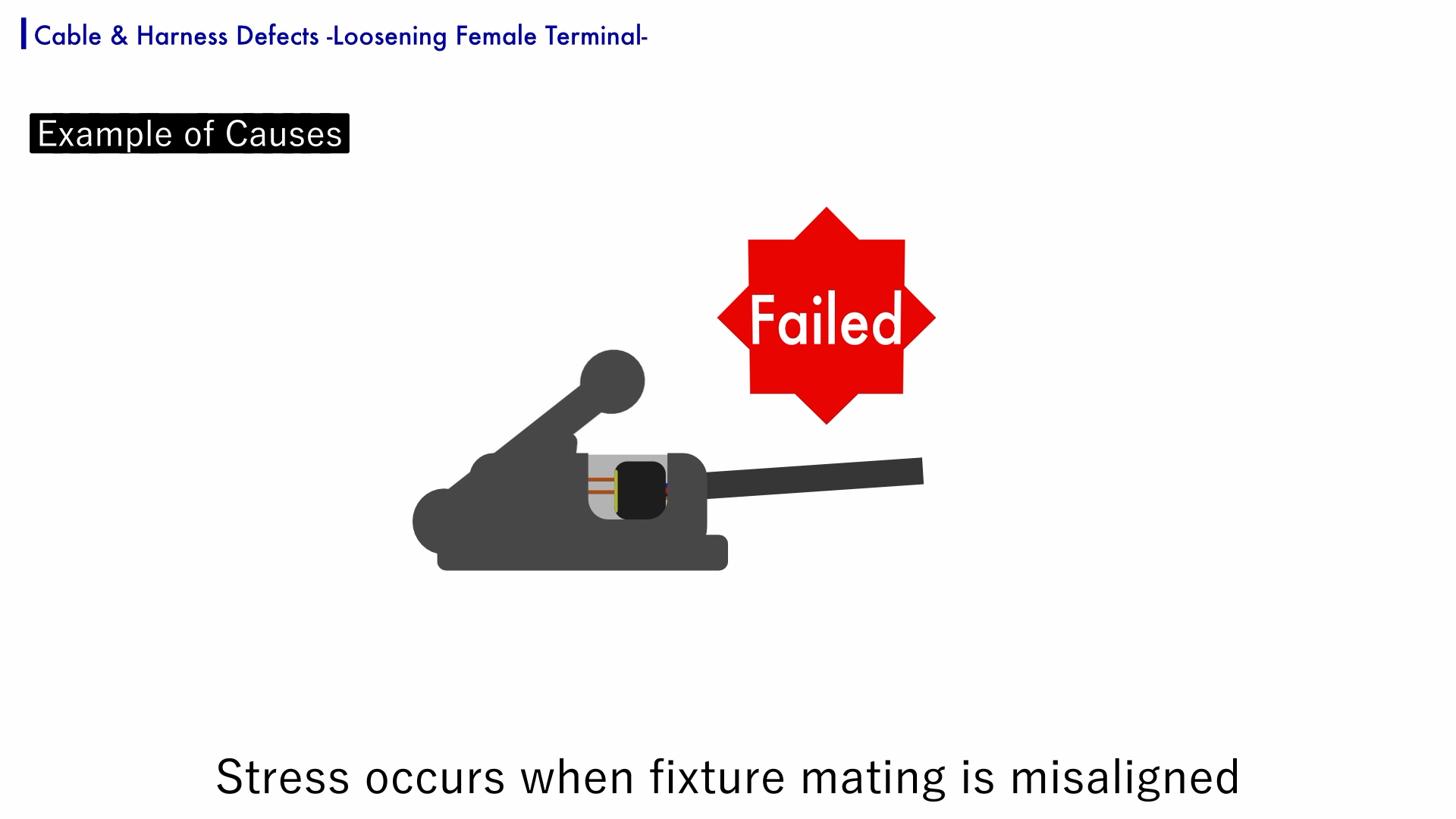

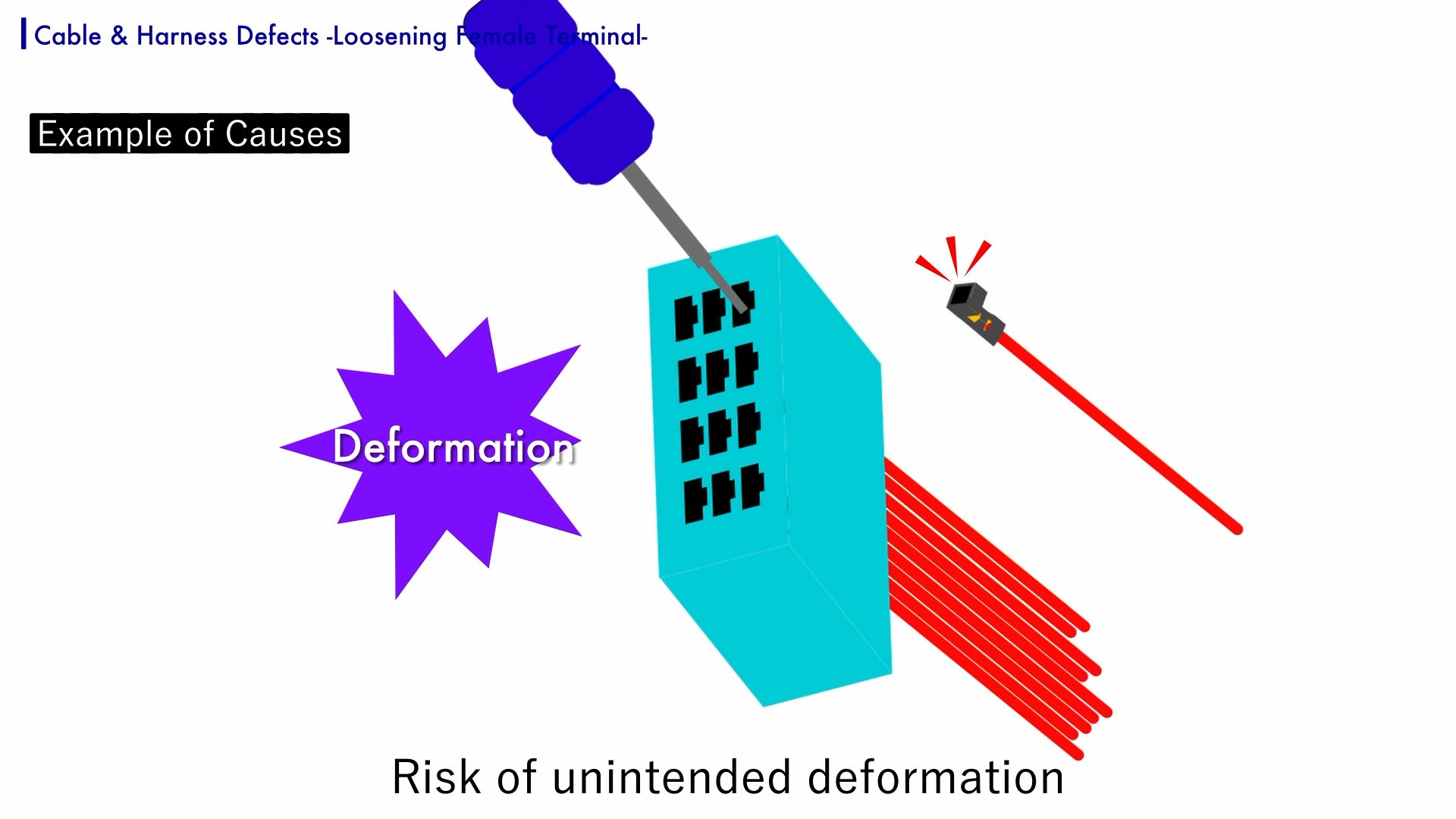

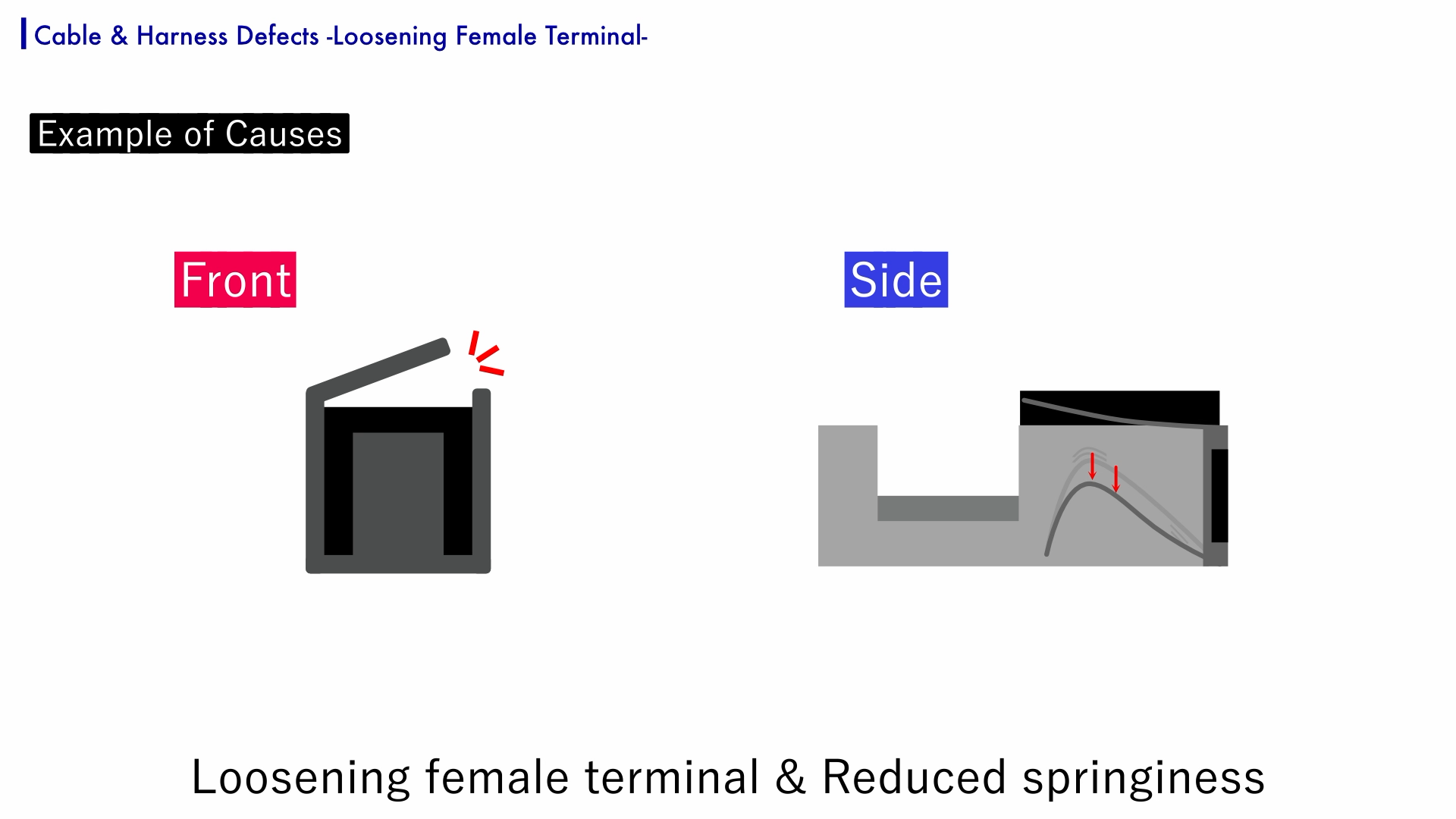

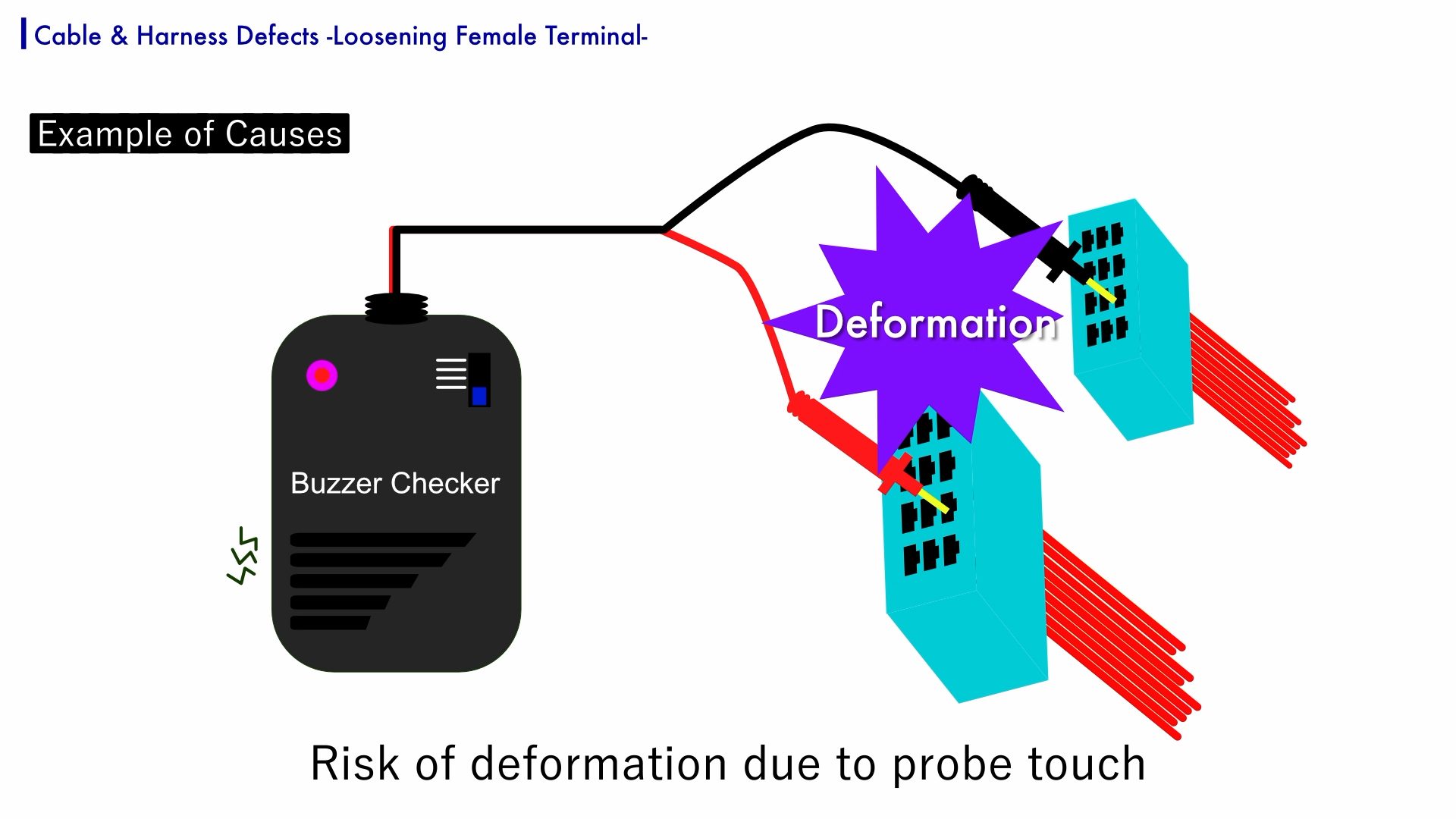

Loosening female terminal occurs during the handling and fixture mating. Narrow-pitch connectors are less strong and more delicate. Human error or mis-mating caused by inaccurate fixtures may damage the connectors and terminals. Terminals are damaged by prying. Deformation occurs by reworking because force is applied to the terminals to open them. The spring of the terminal that stabilizes the contact becomes less effective. There is also a risk with a buzzer tester. Forced touch with the probe will cause deformation.

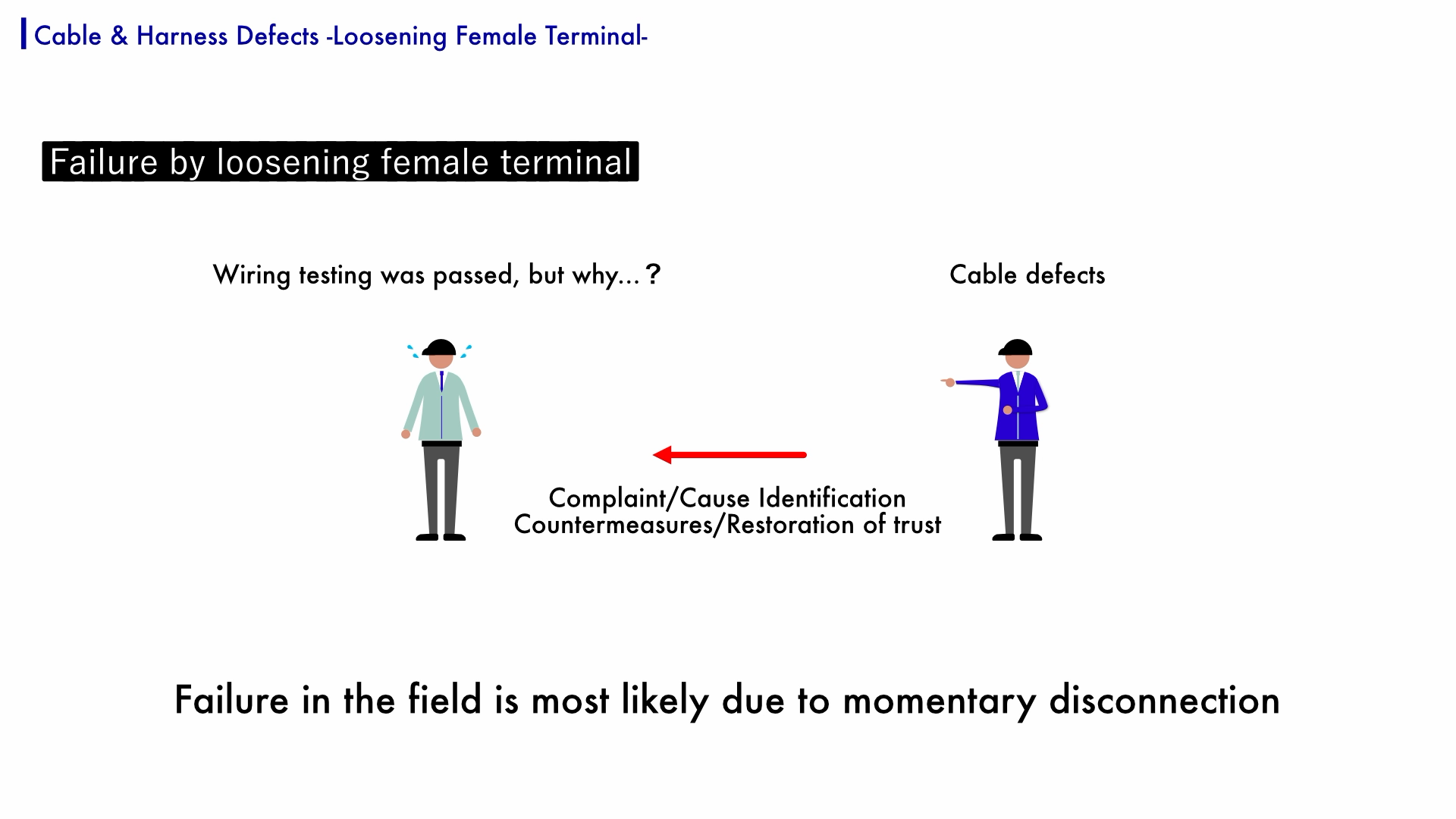

Does continuity exist even if loosening terminal occurs?

Even if a loosening terminal occurs, continuity is still present in the static state because the metals are touching each other. However, the cable harness is not performing to its full potential. The mating force becomes small, and momentary disconnection occurs due to vibration or shock. There are cases in which a product has passed wiring testing and has been shipped, but the manufacturer complains that the product is defective. There is a possibility of momentary disconnection due to an unstripped cable A momentary disconnection defect in the automotive harness will cause the dashboard camera and audio system to stop, and the lamps and side mirrors to malfunction. In the worst case, the vehicle may not be able to drive. Similarly, the detection of momentary disconnections is important in industries such as railroads, motorcycles, telecommunications, and aerospace.

What is the test to prevent the outflow of products with defective terminals??

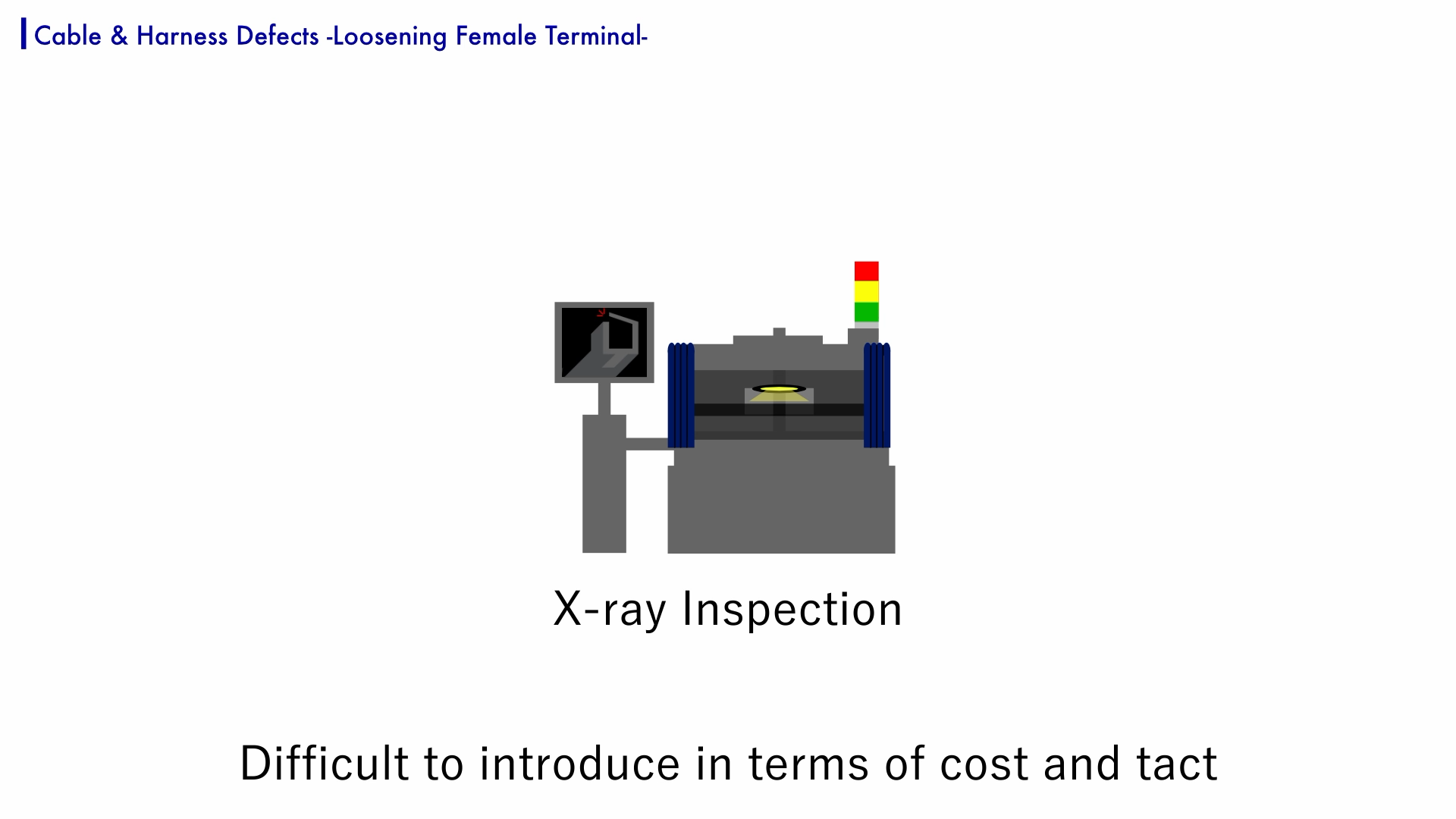

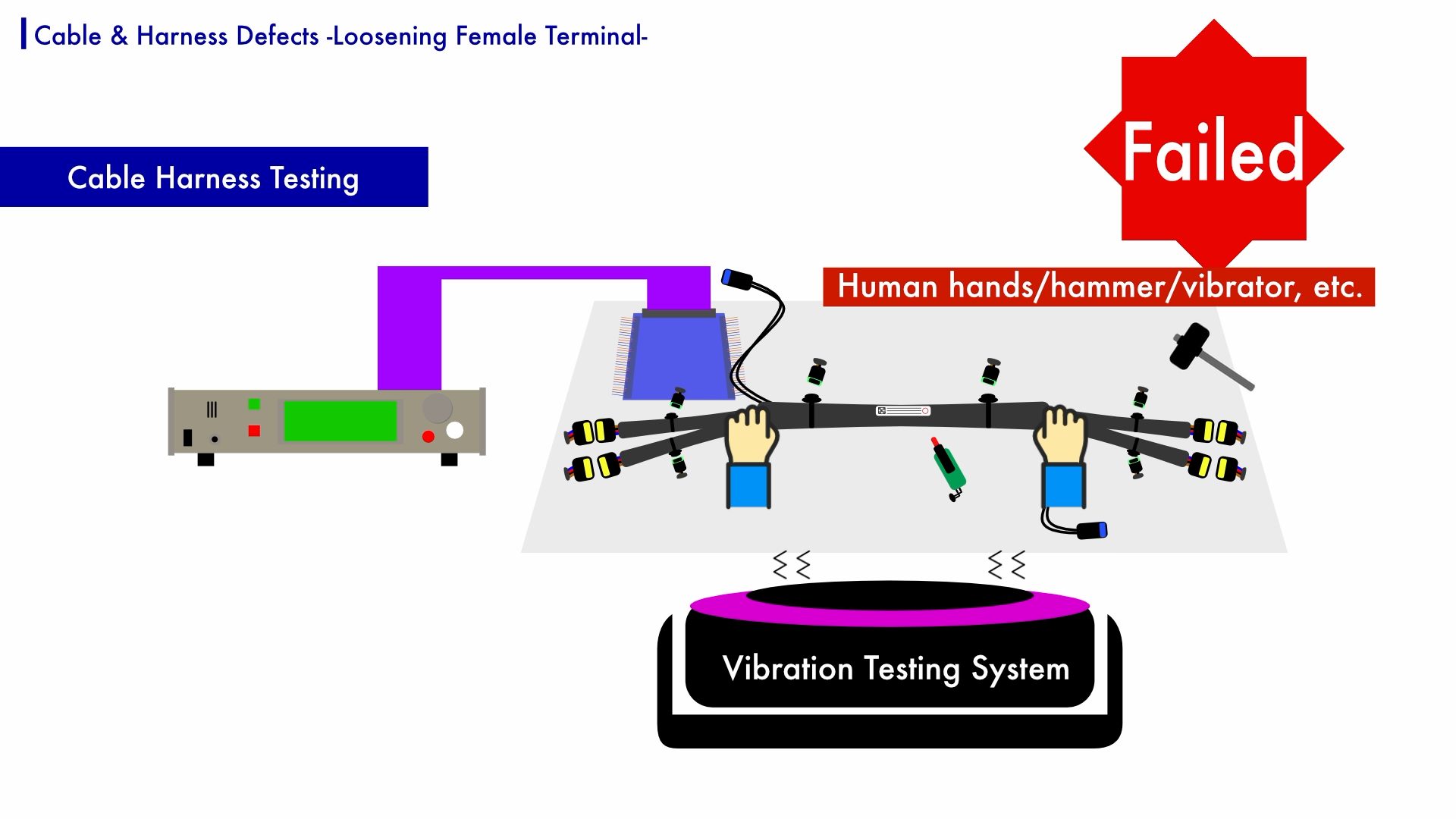

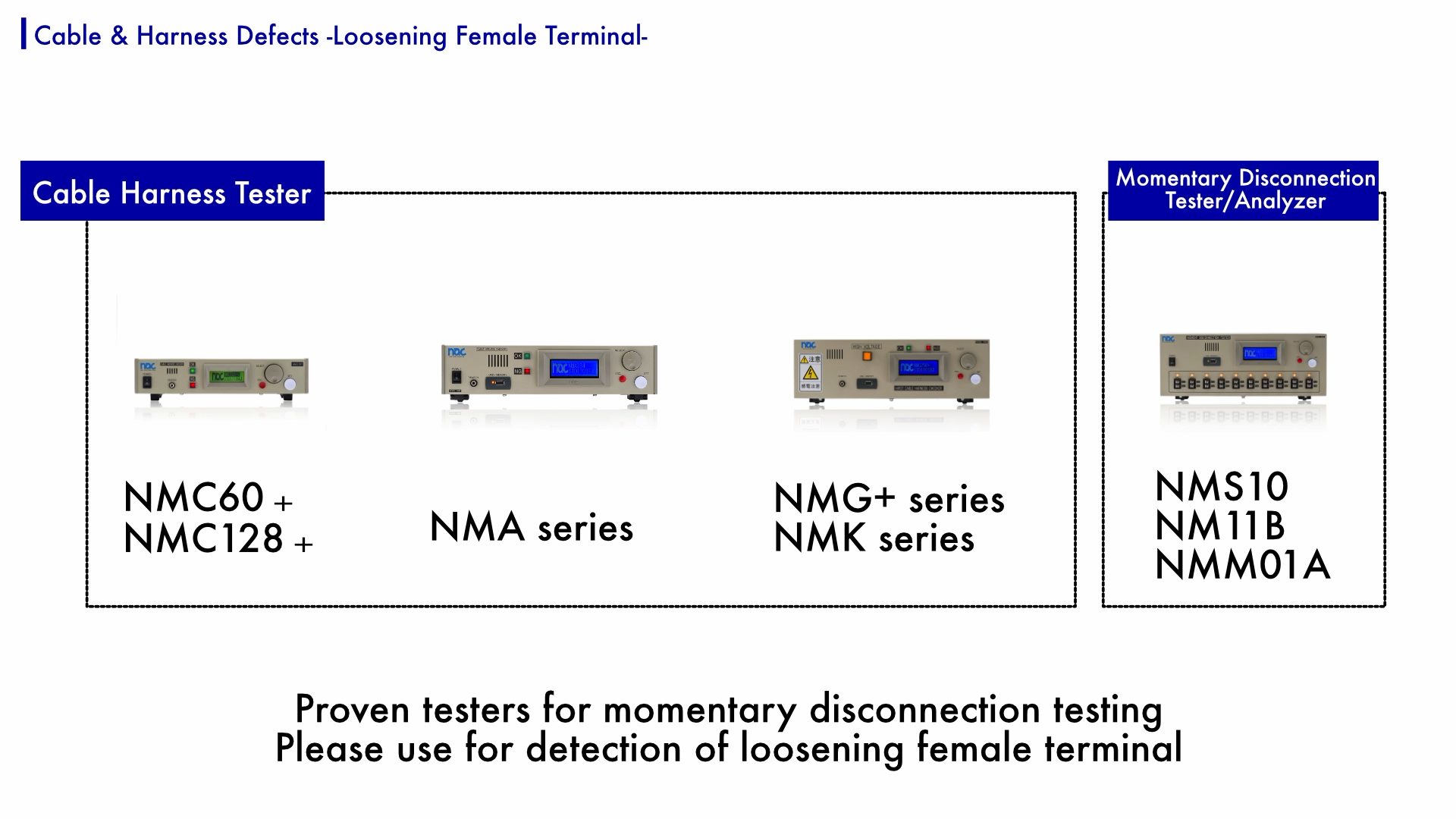

It is not easy to introduce X-ray testing into mass production inspection processes from the viewpoints of cost and tact time. Therefore, it is best to confirm continuity under actual vibration with momentary disconnection testing by cable harness testers. After passing the wiring testing, the momentary disconnection testing is conducted. During the testing, vibration or shock is applied by hand, hammer, or vibrator. The direction of the shock is specified by the standard. It should be considered in accordance with the item to be tested. Mating with a fixture requires precision and careful operation. Checking with a buzzer tester also requires a person to directly touch the terminal with a probe, which may cause unintended deformation. nac CORPORATION's testers are capable of momentary disconnection testing. Please make use of our proven testers for quality improvement.

- Product Search

- Inspection Spec

- Category

- Options

- Discontinued Product

- All Products