[Cable & Harness Defects] Cable Harness Testing for Unstripped Error Detection

Causes and behavior of unstripped (misstripped) wire sheath

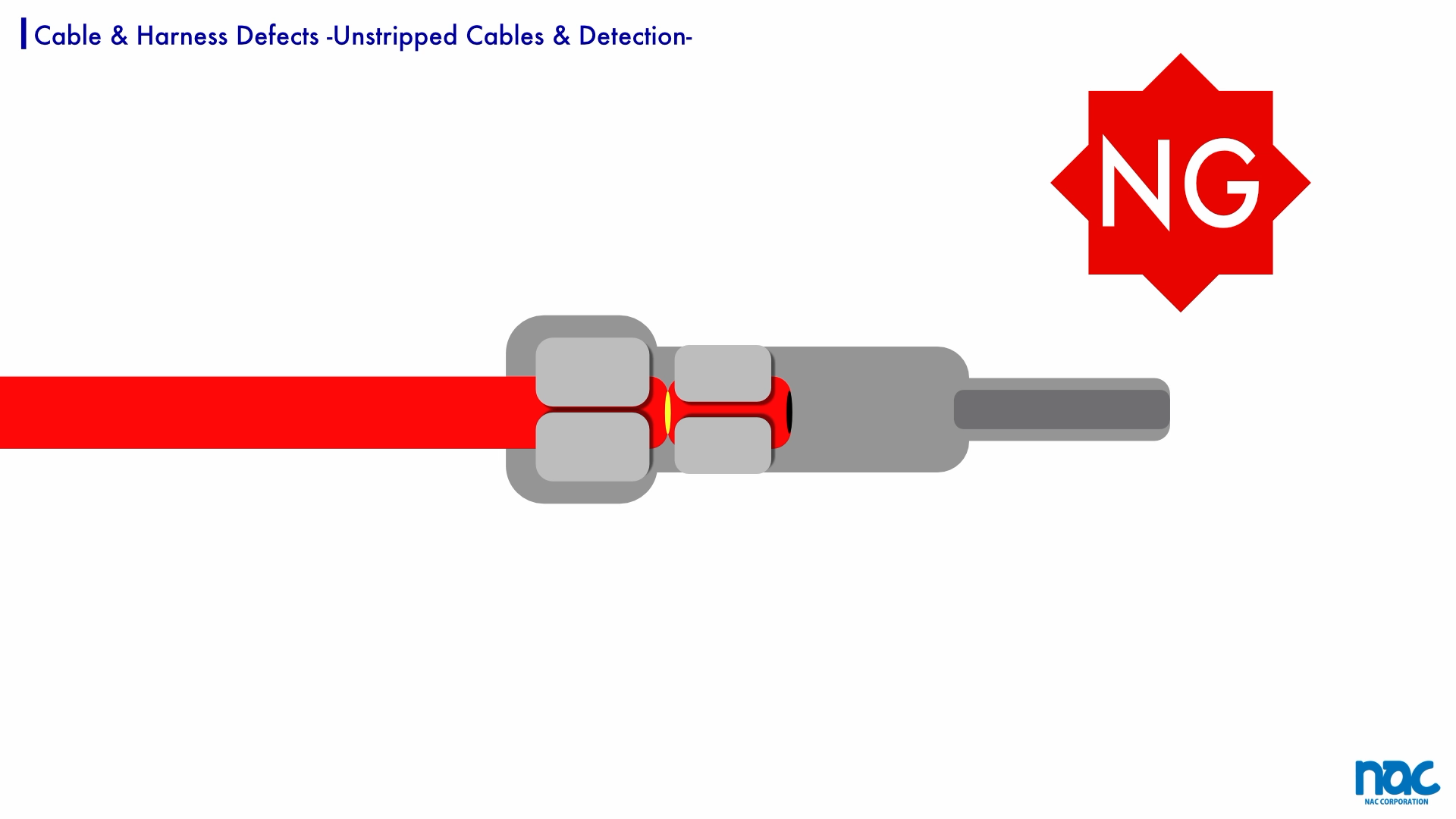

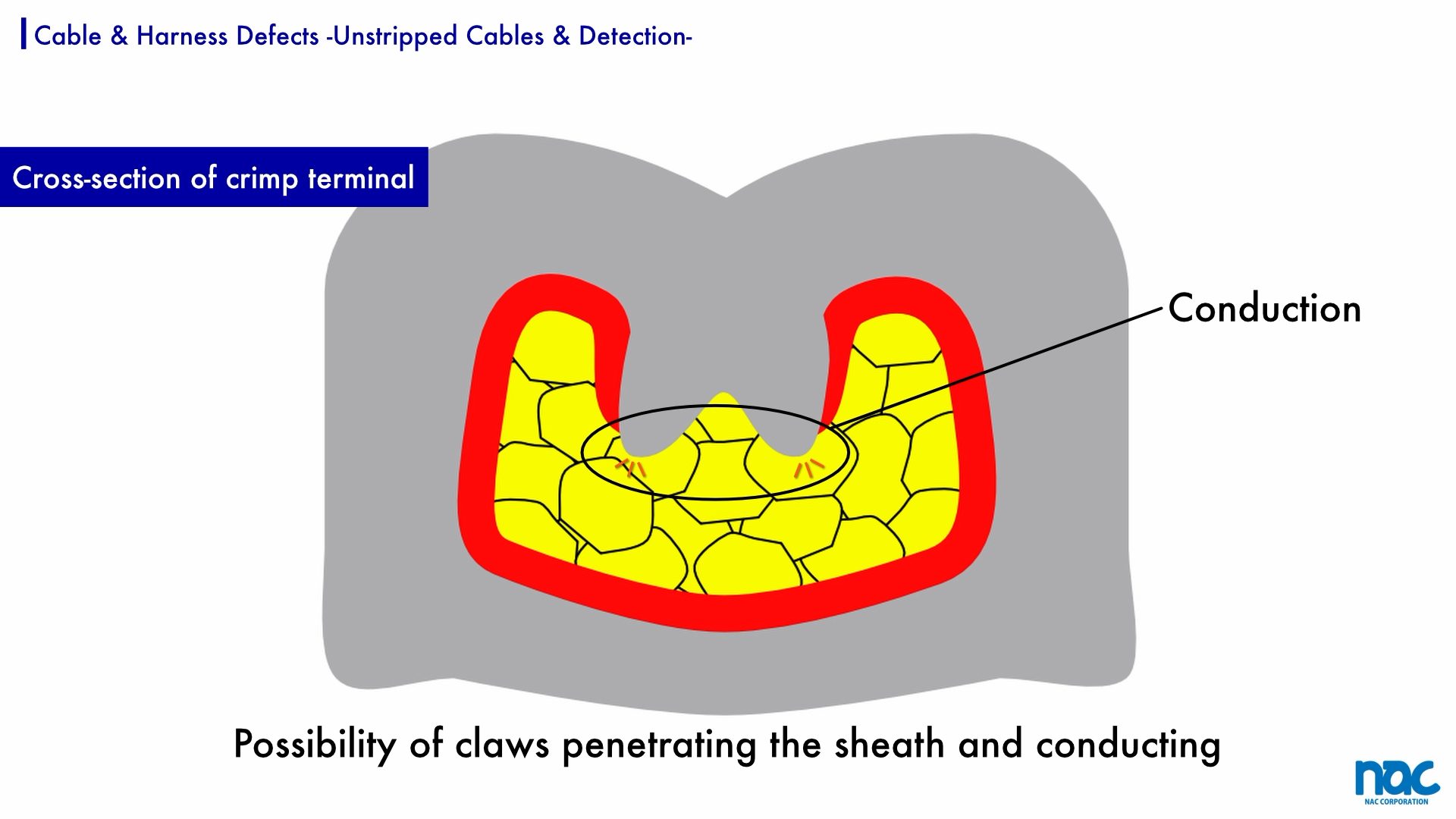

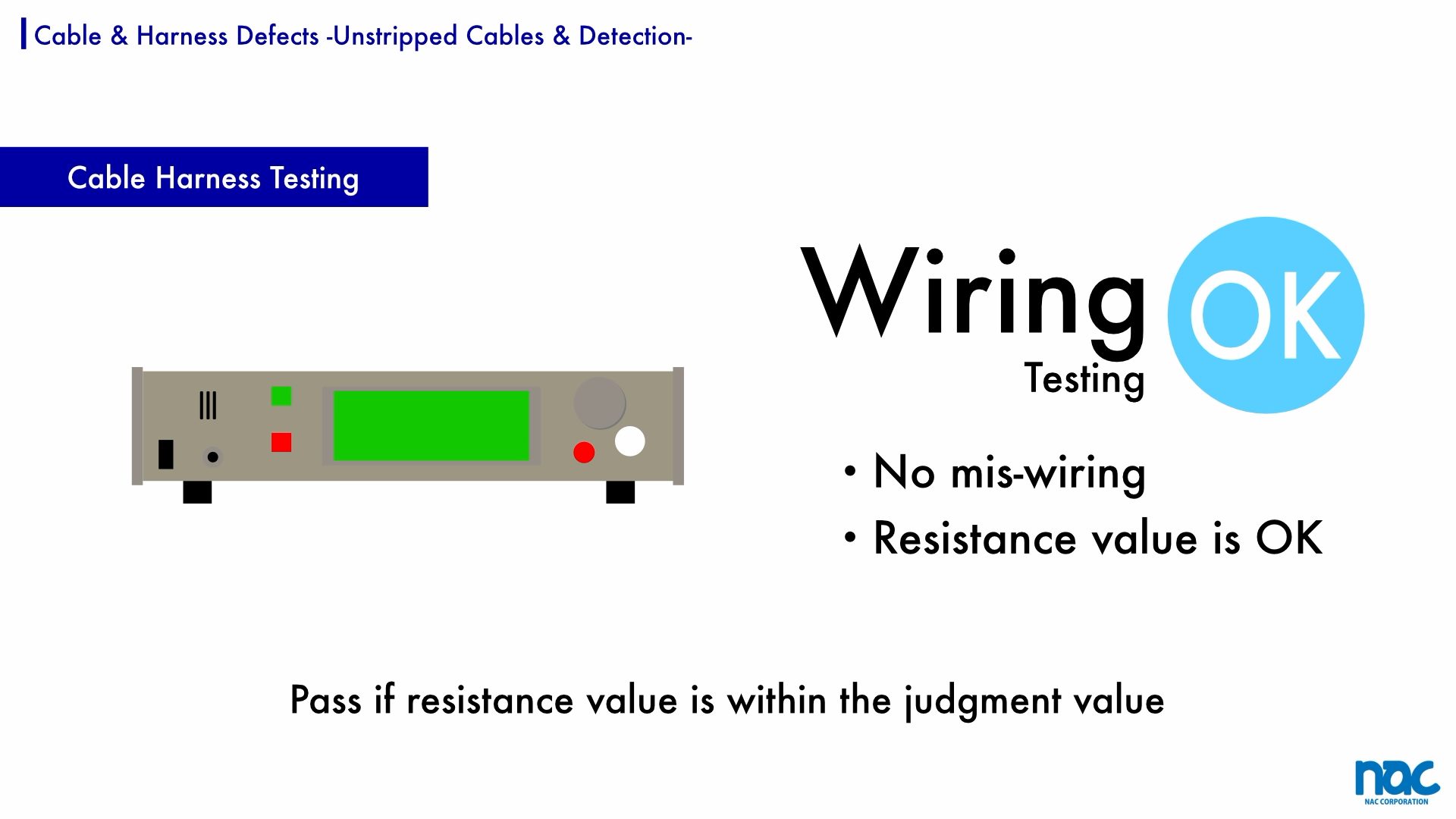

Unstripped occurs due to human error, and machine stripping errors also occur at a low rate. Even unstripped cables may conduct depending on the terminal and the cross-sectional condition. The claws of a crimped terminal may penetrate the sheath. If the terminal and the cable are in contact at even a single point, the product will pass wiring testing, and there will be no significant difference in resistance. However, it is not performing its proper function. Conduction is maintained in a static state. But vibration, shock, and refraction can cause unstable conduction. This is due to momentary disconnection, which can be conductive or non-conductive depending on the environment. If these are released into the field, it could be a serious accident and you will lose the trust of your customers.

Example of unstripped wire sheath failure in the automotive industry

There are cases in which a product has passed wiring testing and has been shipped, but the manufacturer complains that the product is defective. There is a possibility of momentary disconnection due to an unstripped cable A momentary disconnection defect in the automotive harness will cause the dashboard camera and audio system to stop, and the lamps and side mirrors to malfunction. In the worst case, the vehicle may not be able to drive.

Cable Harness Testing for Unstripped Error Detection

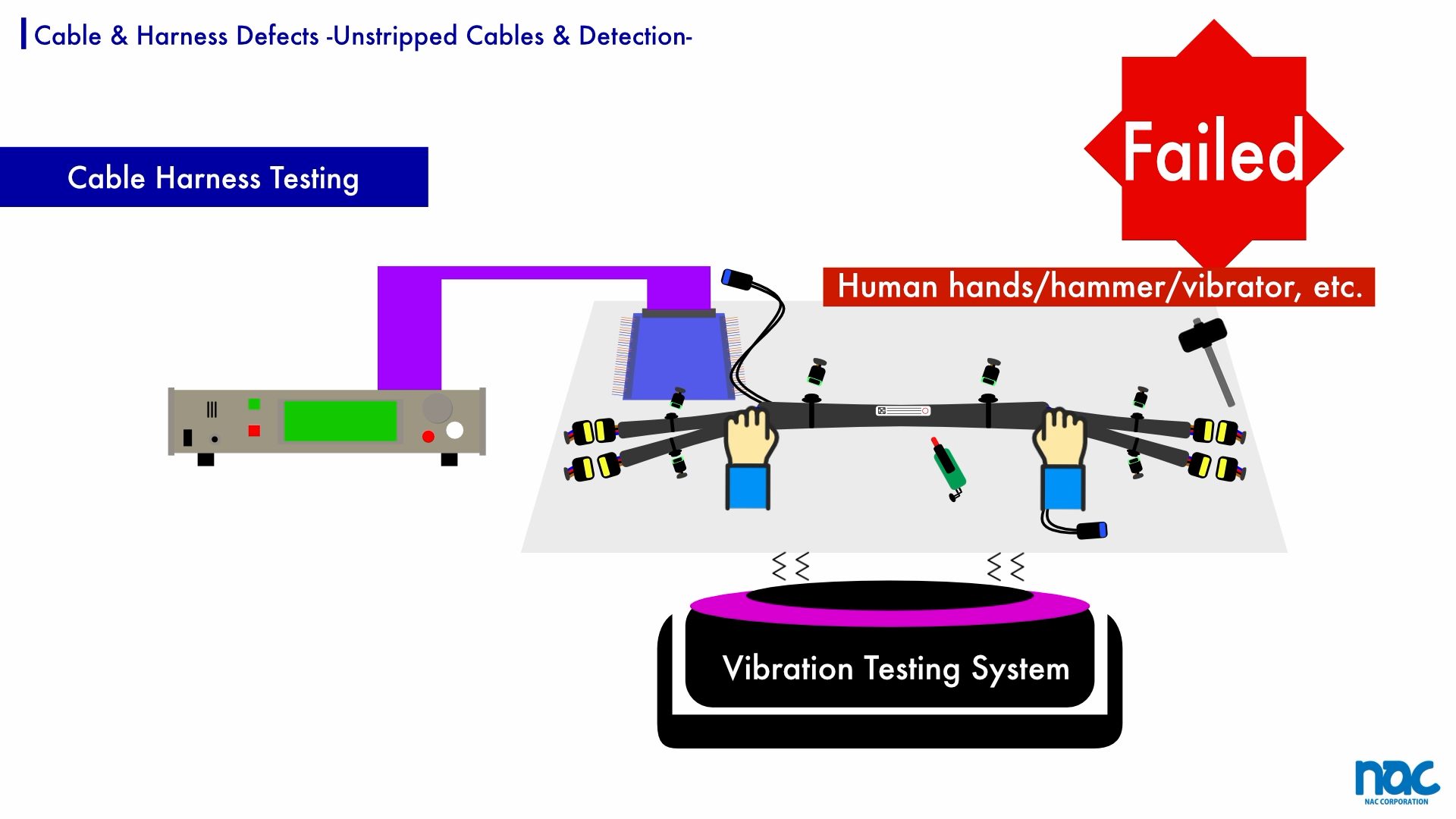

Examples of unstripped detection methods include visual inspection and pressure detection. In the final inspection of a completed cable harness, perform momentary disconnection testing with a cable harness tester. It determines whether continuity is actually maintained under vibration and shock conditions. nac CORPORATION's testers are capable of momentary disconnection testing.

- Product Search

- Inspection Spec

- Category

- Options

- Discontinued Product

- All Products